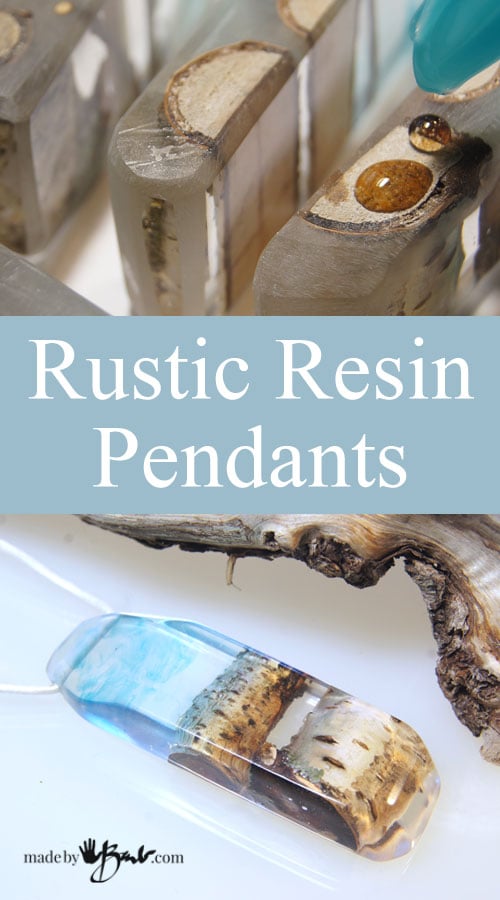

Rustic Resin Pendants

My apologies; I have been really busy with an exciting new media; Resin! It’s so exciting to be able to show you how you can cast and form your own absolutely unique resin jewelry. Natural ‘live edge’ elements are very ‘hot’ and this has so many possibilities… but don’t blame me if you also become a ‘resin addict’! Check out my tutorial; how to make your own super-unique jewelry:

My starting point was again nature. I took some inspiration from Britta Boeckmann‘s early jewelry but wanted to be even more rustic. I am always wearing pendants, the type that make a statement. Nature supplies so many textures and designs if you open your mind to the possibilities. Go! outside! and check out what nature has to offer. There are so many amazing pieces of wood and branches and bark and leaves and… It just boggles the mind.

The Resin:

I am using a readily available resin called Alumilite Amazing Clear Cast. It is sold by many hobby and craft supplies and quite reasonably priced. It is not a polyester resin so I don’t find that it has any toxic fumes however it is still suggested to use under well ventilated conditions and avoid skin contact. (once cured, it is food safe though)

The Imbeds:

I collected a variety of wood branches. I love the great textures that bark and birch have as well as the lichen that grows on it. Anything can work within reason, that it is not too rotted or soggy. You will however need to let any wood dry thoroughly or use a very low setting to dry in an oven. Resin doesn’t like moisture!

Also, prior to embedding I like to ‘stabilize’ the wood as much as possible if it is old or soft. Stabilizing means making the wood more solid, as replacing some of the ‘air’ with a solid product. The professionals use a pressure chamber and force ‘cactus juice‘ into the wood. I use a paintable product; ‘Wood Petrifier’ that does a similar job and easier for the DIY’er. Give the pieces a good coating or 2 and let thoroughly dry. It sinks right in. The pieces can be used whole or cut as preferred, but keep the design simple. I had definite visions in my mind’s eye.

After prepping the wood I arranged how I wanted the pendants to look. I was anticipating cutting them after casting. I used a small shallow square silicone cake mold that was slightly greased with vaseline.

Mixing the resin:

The key to a good cast is having absolute exact measuring. This resin uses equal parts of A & B. I use tiny transparent cups that allow reading volume easily. Mix slowly but thoroughly until it is very clear and has no striations. Do not get over excited stirring as you don’t want to mix in any air bubbles. Scrape the sides often to make sure all is completely incorporated. This resin is quite slow to set,(30-40 minutes working time) so it lets you play with the arrangement of the items.

Here’s an important trick: WOOD FLOATS! Yes, I found that out the hard way! Pour as thin layer and set your pieces onto it. Let this cure until it is set. This will keep the wood parts from floating once they are covered with the rest of the resin. For colour I used a tiny bit of Pebeo Vitrail Ink to slightly tint the resin (turquoise). You can also have fun with leaving the swirls visible. (mix with toothpicks) I wanted the wood to be completely embedded and poured another layer to cover.

Once it is poured, a small lighter/torch or blowing with a straw will make the bubbles that are on the surface burst. Sweep quickly across the surface so as not to scorch the resin. Let it sit 24 hours or until hard. Once unmolded, I will decide the shapes I’m going to use. If your mold is the exact shape then you can skip next step.

They look wonderful and clear!

Shaping:

To cut the shapes I used my new Dremel Moto-Saw Scroll saw. It is a a great little/mighty tool or beginners who do not want to use powerful tools. To protect the resin I covered it in masking tape. Slicing them length-wise across the branches gave me the long shapes I was after.

The wood has now been sliced through as well.

Once untaped, they look wonderful already, like little blocks of frozen ice!

Finishing the Pendants:

To even out the sides I used a rough 200grit sandpaper.

Working with resin has some downfalls; sanding! My intention was NOT to make any dust by dry sanding, as it is a nasty health hazard! Once the surfaces were pretty even, I mixed up a bit of resin and spread it carefully over the rough ends, and let it dome. Do not over-pour or it will drip down the sides. Just drip a bit and spread it out, it will self-level.

I wanted all the wood to be encapsulated in resin to allow wet sanding without the wood pieces absorbing water.

You will see the great shine it also makes.

Coming along nicely…

Wet Sanding:

Once they are coated on all sides, the wet sanding can start. Once Alumilite is cured it is food safe, and the water keeps any dust from forming. I use a large cafeteria tray to catch any stray water and work through the grits of wet/dry sandpaper.

The sequence: (wet/dry sandpapers may be found in the automotive area of the hardware stores)

- 200/220 grit – rough shaping

- 400 grit – medium smoothing

- 600 grit – medium-fine shaping

- 1000 grit – fine for removing scratches from shaping

- 2000 grit – super fine sanding

- Novus #2 Scratch remover (liquid polish)

- Carnauba Wax for shine

Shaped with 220 grit

Edges softened with 400 and 600 grit.

Further smoothing with 1000 and 2000 grit.

Polished with Novus #2

There may be other polishes that also work, but these are great. (and who knows if the car headlights will need some someday). Inspect your piece and backtrack if you find scratches. Use some muscle to be thorough with wet-sanding. Rinse in between grits (keep a bowl of slightly soapy water handy) When it looks good, use a car wax or the Novus #1 to shine the piece.

Finishing Touches

To be able to hang your pendant you will need some sort of way to hold the chain or cord. Bails are available that can be glued or attached with a small hole. I decided that a drilled hole would be simple and strong.

My Dremel is mounted in a Workstation to allow drill press type work. It is a super handy addition to the already great tool.

It is so satisfying to see such a transparent shiny artifact that is hand created and can also be worn. See more here

Closeup inspection and you see the lichen frozen in time.

Be creative! And proudly wear your piece of unique jewelry! High five! Alright, alright, if you’d rather just buy one; check out my new Etsy store. It’s what happens when you just love ‘making’ and make too much…

LOVE THIS one Barb! Worth the wait!!!

WOW

Thanks, you are so sweet! Etsy store is in the works. I need more hours in the day!

Beautiful little works of art!!!

Oh Thank you! I love nature and now can keep a bit encapsulated… So many options!

Thank you for being so giving with your knowledge! I’ve been waiting for someone to share how to make these exquisitely made jewels! You’re greatly appreciated!

I always make sure I actually try and perfect the techniques. Isn’t that what tutorials are for?! I hate just seeing the same rehashed.

Barb, I have been playing with resin as a protective coating for polymer clay but haven’t tried casting anything. The only resin molds I’ve seen are for pendants, cabochons, etc. Where would I find larger ones that would hold found objects from nature?

Hi, nice to here that you are having fun! The blue ones are just baking molds for square cakes or chocolate. They were at out craft store here in Canada called Michaels. You could prob also use silicone bread pans. I’ve even seen small ones at dollar stores. Hope it all works out

WOW. Beautiful and amazingly creative designs. Thanks so much for sharing. 🙂

Glad you stopped by! I have some ideas brewing in my mind, I’m hoping to get back to the resin pouring soon! So many possibilities, need more time….

I am trying your method, but having problems removing bubbles. Tried a blow dryer at slow speed, wants to push the resin out, can’t use a heat gun, or small torch. Mold will not stand up to it. Any ideas.

You can even use a straw that you blow into to pop bubbles. Apparently letting the resin pour into the mold in long thin stream gets bubbles out too.I used the straw method but be careful with the humidity from your breath… Hope that helps. The torch/lighter is a really quick pass over btw.

I have used a straw and blown the bubbles, just be careful with the humidity that comes from our breath. The torch is a quick pass, not really heating anything up. The bubbles pop right away. Pouring into the mold in a long thin stream also eliminates bubbles. It may take a bit of practice. Don’t stir too crazily as it will add air.

Hi

Thanks so much for sharing with such complete details! Beautiful work..definitely going try this.

Yes, I understand that many times the instructions are not that thorough. Glad to help! ‘Would love to see the finished ones!!

Thank you Barb for sharing your excitement in working with resin! I started to play with resin at one time but must have gotten sidetracked, which happens all too often, with another idea, medium, or project. And thanks for photographing the steps and sharing some tricks in making your awesome pendants. I am ready to try it again!

I know all too well about getting side-tracked! I have so many different types of thing I do that all the work stations are taking over the house! I have a big collection of things that I am hoping to imbed as I keep getting more ideas…DIYing is really just a long journey! Check back, I’d love to see your projects

I have been wanting to do this for some time but there were just too many elements I couldn’t figure out. Thank you for this in depth description. Question: Where did you get the molds? Everything I’ve seen starts with a large mold that you then cut down. The problem with sanding resin is it becomes rather cloudy. I’ve tried the sanding but it never turns out well. Plus, the best way to get shiny resin is to have shiny molds. So my obstacle has always been finding the correct mold and figuring out how to dry the wood.

The molds were just from Michaels (canadian version of Hobby Lobby ) They did not unmold shiny either. The easiest way to get a shine is to coat it with resin. Otherwise you need to sand and progress to polishing compounds. You can dry the wood in a low degree oven too. I did a few test pieces at the beginning… Even the molds I made with amazing mold putty did not give a shiny finish. I am not a fan of tons of sanding or dust, so I used wet sanding and coating with resin.

Hope that helps! Let me know how it goes…

Hello!

I was wondering to know if Pregnant Woman can work with resine or if it is toxic to the baby?

There are different versions/brands of resins. The one I used is this: Alumilite Amazing Clear Casting Resin and there is a safety data sheet here

I can not guarantee any information and I would suggest direct contact with the manufacturer. https://www.resinobsession.com/ gives much good info as well about the various types.

good luck and be careful…

Hi Barb,

Like everyone else thanks so much for putting this up! I usually work with metal but just love what can be done with resin and since relocating to the States from New Zealand the range of resin and all kind of “goddies” has just expanded 100 fold. I did try once but guess my resin wasn’t the best, so the only question I have for you is when you do the final polish do you do that by hand like the sanding (good ole elbow grease) or do you use your dremel? … Thanks so much!! Nikki

Thanks for visiting! I use my hands. The dremel I had at the time was too fast. If it spins too quickly then the resin heats up. I am sure the professionals who make them by the dozen have a polishing wheel. I also did not like how the compound would fly off the polishing head. Ideally one would need a dedicated space with good dust catching etc. So for ease of keeping mess down, I used my hands! Put on a video and it will be less boring. It may take a few before you get the hang of the stages of sanding. Every media has a learning curve… Good luck

Barb, are you sure we aren’t twins separated at birth.

I love everything you do! Resin, soap, concrete, hypertufa are all things I have done or aspire to doing, and.. I like your style. Now if you tell me you are also interested in bees & plants I might fall off my chair.

I’m looking forward to your next creative endeavour.

Regards,

Barb

Hi Barb! I know for sure that I don’t have a sister, but that’s quite amazing! If I lived on a different property I would definitely have bees! I had recently been thinking if there was some kind of project that would help their plight. Sometimes I have to remind myself that I can’t do everything… and have every tool and work area going… I wear myself out! Do stick around as I have some completely new projects in the works. I bet you like the terrariums and the dyeing too!