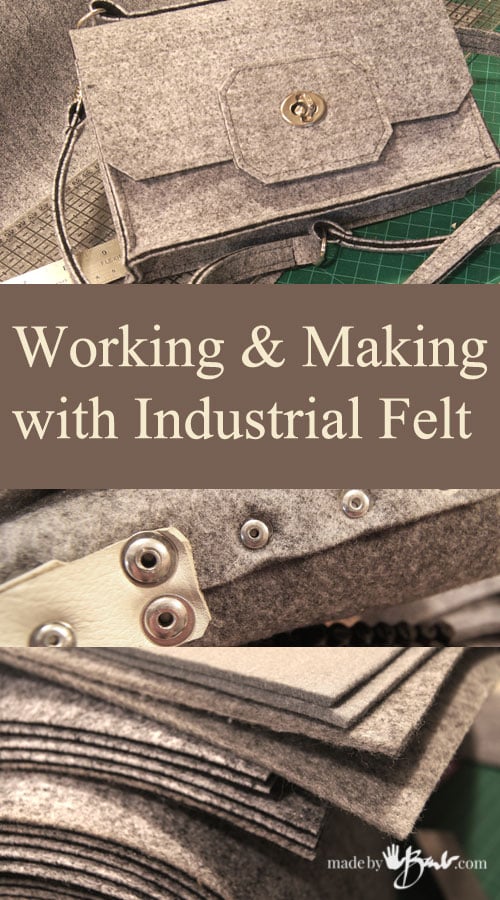

Working and making with Industrial Felt

I discovered something wonderful over in Germany! Schnitzel! – kidding… No, I found heavy-weight industrial felt in a fabric store and was instantly in love! It is grey wool and 3mm thick, which makes a wonderful media for a variety of ‘making’ such as bags and purses, containers, footwear etc… I immediately put it to the test. Working and making with industrial felt is actually quite easy compared to usual sewing practices.

What is felt?

But first, what is felt? Felt is the short word for a variety of material that is made by the combining of fibres without knitting or weaving. The fibres are matted by some method of twisting or vibrating until they become so entangled with each other that they hold strong. It’s really the same as how one turns their hair to dreadlocks. Original felt dates back to as much as 6,500 BC. It can be hand made, manufactured or even made by having huge rolls dragged behind horses to matt the fibres.

Depending on the fibres and thickness it can even be used for furnishings. I just love how versatile it can be. See here for some very innovative work by Freya Sewell. There are interesting stories of mongolians pulling rolls of felting behind horses til strong and thick. That thick felt provides the protection on the walls of the yurt. Felt is breathable, warm, strong, but also tends to be light for it’s size. Anyways… on to the fun…

Cutting and Punching:

As you can see, the fibres are very densely matted and have no direction. For that reason, it can be cut and will not unravel or fray. That makes less work of finishing edges! Another designer’s dream! I used a rotary cutter as well as a matt knife with straight edge. It allows for perfect edges. Using a cutting matt keeps it square and easily measured and protects your table.

As an artist I have cut much matt board in my life, it is always good practice to cover the part of the fabric that is the ‘good side’, just in case you veer off direction while cutting.

To allow for sewing or attaching hardware, you can also punch it with metal punch tools. Make sure you have some soft material to make sure that your punch does not dull.

Sewing:

Another of the major advantages of felt is that even though it is strong AND thick, it can usually still be sewn with a machine. That is one of the frustrating problems of leather; it is tough to sew on a regular sewing machine. My felt was 3mm and I had no problem sewing 2 thicknesses as the needle does not have a problem getting through. My other felt (polyester, I suspect) was thinner but denser and was still easy to sew. Due to it’s density and stiffness it was sewn on the ‘right sides’. That gives it an industrial charm.

Folding over the edges makes for a roll type rounded handle strap.

My favourite is the grey colour as it has more industrial-loft look. The speckled grey is very forgiving and timeless. Silver hardware matches perfectly and top-stitching finishes it off.

Pop Riveting:

If, however you choose not to sew, you can still attach with the aid of pop-rivets. Being able to use ‘tools’ makes for even more fun! The addition of washers to the rivet gives more ‘bling’ to the design.

Pop rivets come in a variety of lengths and sizes. They are unique as they work by pulling the material together from the right side. The rivet is inserted through the holes in the material thicknesses, a backup washer is inserted on the inside, and then the rivet gun pulls the shaft from the outside (the bulbous end is pulled through the end which anchors it) and the shaft breaks with a ‘pop’ and then comes out.

The hole is where the shaft was. I sometimes use some washers for build up of thickness or visual effect. It gives a very industrial look and is very strong. You could substitute hammer rivets that would need hammering to force 2 parts together. Myself, I find getting the hammer into tight spaces is harder than pulling the rivet gun.

New designs to be posted soon with patterns. Oh so many possibilities! The hard part is deciding which one to make… Felt has great stability as it is flexible AND holds shape, a designers’ dream!

Here are just a few samplings but do check out my simple No-Sew Bag or super easy Fold up Box (each have downloadable patterns) Have fun ‘felting’…

Great project. Love the look, industrial but refined looking. You continue to amaze me with your ideas and talent!

You would love to work with this stuff too! My brain is overflowing with ideas! Stay tuned…

I just want to mention I am beginner to blogging and site-building and really enjoyed you’re web page. Probably I’m want to bookmark your blog post . You certainly have really good articles. Cheers for sharing your blog site.

Glad it could be of some help!

Thank you so much for the tips. Do you have a website that you could suggest where I could purchase the Wool Industrial Felt?

Thanks! If you are in canada there is a great supplier; http://www.thefeltstore.com/

I have used some that I brought from Germany and also a automotive decking material that acts like string felt. You can order online but I always like to ‘feel’ my fabrics or felt. So perhaps a small order or samples would be best. Good Luck! It is such a great media!

Barb, you are a genius……

I wish certain people thought that! I’d say I am more likely just stupid-determined most of the time. Generally most want to give up before they even start, as an excuse…

Barb, what kind of sewing machine do you use? My machine won’t go through two layers of felt.

I love my vintage kenmore machines! They are all metal and quite the workhorses. They show up quite often at thrift shops etc. Good luck!

Thank you so much for sharing this detailed and well -photographed tutorial.

If only you saw my photo library! It’s always bursting at the seams, not to mention video files. Oh, I just had an idea; as I realized I haven’t felted on that thick felt… yet! Oh my, that could make some magical purse designs!

Glad I found this by googling about sewing felt! Thanks for the rivet idea, I think they’re gonna cover 100% of my needs for making some simple pouches with laser cut felt for random tools and electronic devices

I’m so glad! That is great! It will be so gratifying! Good luck!