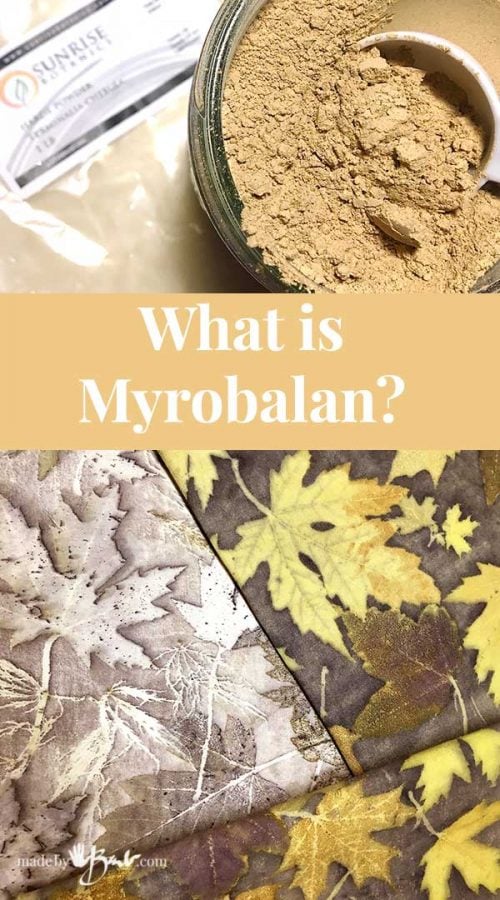

What is Myrobalan?

Eco printing may have your head spinning with all the variations! Well, let me introduce another amazing player to this fantastic magical game; Myrobalan. This important tannin based mordant can yield awesome results…

Where does Myrobalan come from?

This mystery dyestuff powder is made from the ground nuts of Terminalia chebula tree. This upright tree has lovely bright yellow flowers and can be found in the forests of diverse regions of Asia & foothills of the himalayas. It also can be found myrobalan extract and also under the name of Harde Powder. It is believed to have some interesting healing properties in traditional Indian medicine. For that reason it did not scare me as many of the other ‘chemicals’ do. ‘And it was easy & inexpensive for me to order it from a local health food supplier and also be fond at some ethnic food stores.

What does Myrobalan do?

This unique myrobalan powder material is both a tannin and a mordant. It is a common dye that will produce nice buttery yellow (20-30% WOF) and provide good mordant for difficult to dye cotton fibre if used before alum at 15-20% WOF; weight of fibre). Since it gives a nice warm yellow it can also be combined with indigo to further add beautiful teal color (single indigo dip).

Scientifically, Myrobalan has some key properties to help with dyeing such as Gallic and Ellagic acid; hydrolysable tannins.

Since I am a hands-on person I tend to learn more by experimenting & doing rather than by reading. For a good foundation I put it through a few tests and observed what it can do. It is interesting how many different outcomes I had.

Understanding the Challenges of Eco printing:

Achieving colours on cotton fabrics in the world of eco printing can be a bit of a challenge depending what species of leaves that you can find or what other natural dyes you add to the mix. This brownish yellow powder dyes a light buff color. Myrobalan also loves iron! Whenever there is any way of the two coming together it creates a nice purplish grey. The depth does depend on the strength of both the Myrobalan and the iron, as usual. I much prefer it to the some of the dirty types of browns that some tannins create with the saddening of iron.

These are examples of a few media including paper and Rayon (considered cellulose fibres). It’s use is not even restricted to the usual rolled bundles of Eco Printing. (watch for future detailed posts) I can also see how stable some dyes are by how much they stain my hands and also my plastic sink; wow did I need to clean!

It is so amazing to see the reaction take place! A cooled tea made from the Harde Powder (myrobalan) has some drops of a weak iron solution (iron sulfate + water) added and immediately the dark greys appear! That is how I do test some of the strength as well. Is there a definite rule? No way…

Combining Methods:

Shown above are some of my favourite dependable printing leaves, iron blanket and a pre-dye of Myrobalan. I bet I know what you are thinking; so what are the recipe amounts? It depends on a few things? What ‘look’ are after? Do you want subtle tones/low contrast? Or do you want very dark background? As you may know; eco printing has many variables such as leaf species, processing times, fibres, water and strength of iron (to name a few). The more you experiment the more you will start to understand the differences you see (this post has comparisons of methods)

Not sure what method you would like? There are so many ways to use Myrobalan in combination with everything else, especially a rich natural tannin of a certain leaf specie.. I often throw caution to the wind and let it surprise me. Is this not art?!

Using the Myrobalan tea (strong to weak) before printing (if a leaf does not have enough tannin) will create a more ‘resist’ stencil type look (top) if using an iron blanket (bottom) or switch it all around backwards (middle) and get a very different detailed effect. (posts coming soon)

This cotton canvas is pretty heavy weight so the textures are much more pronounced since the thickness of the fibres comes into play. The ferns tend to not have much tannins to print on their own but work well with the Myrobalan to act as a resist for intricacy of shapes. The soft butter yellow use adds a rich design.

So grab yourself some Myrobalan and maybe it can even come in handy for whatever ails you… Happy Printing (watch for future detailed posts)

Thanks for sharing your amazing experiences❤️

I tried it today. It was magical, Thought the iron solution was too heavy and the darkness became out of cotrol😅

You can try a dip in a diluted citric acid solution, that will lighten darks from iron as well as the stains under your nails… I would be careful, test a corner and watch carefully.

Hi Barb

Loving your posts, thank you so much. Could you explain what you mean by a Myrobalan ‘tea’? I have managed to find some powder, but not sure how to make the tea from that. Would really love to know your process, and quantities to use.

Thanks so much in advance,

Petra

It is just like making tea. It does not need to be boiling water but it dissolves better in hot water. It will be a bit gritty as it’s a powder but I find it does not matter. Once the fabric goes into the ‘tea’ it will take up the dye. It’s how most natural dyes are used.

Thanks Barb. That sounds easy enough then 🙂 I’ve not used any powdered natural dyes – only the long way, by extracting from the actual plant matter.

Will definitely give the Myrobalan a go!

Barb- do you dye the cotton with Myrobalon , dry, then mordant with alum ? I have some, but didn’t know what to do with it. I’ve been working on silk, but would like to try cotton and linen

Myrobalan can be used to dye and then use immediately before drying to eco print. I have also discovered that it can be used without a pre mordant like alum on cellulose fibre. I had great results combined with an iron blanket for the linen top As a way testing the longevity I throw some printed scraps in with the laundry repeatedly to see and the myrobalan/iron combo lasts well. It’s one of my favourite combos. Do scour well though.

Of all the eco-dyeing websites, yours is the best!

I have two questions:

1-Will washing linen in the machine with Synthropol be sufficient to scour?

2-Is there a reason WOF percentages are used rather that the proportion of a given product to an amount of water? The latter sounds so much easier, but maybe there’s a reason it doesn’t work?

Peggy

P.S. Myrobalan is easy to come by if you search for Harataki powder on Amazon.

The linen I find is usually from some other use like a curtain etc. I like to use a very very hot water and washing soda with a bit of Dawn to scour. I leave it for as long as I can. I’m amazed at how yellow the water gets – so gratifying!

The WOF is to ensure the content in the water is enough for the fibre. In my mind as an artist I tend to be a bit rebellious and not always get caught in weighing. I don’t mix paint by weighing either. Some like predictability…

I find Myrobalan in ethnic shops under Harde Powder, locally!

I enjoy your posts. Like you I don’t measure accurately and sometimes fly by the seat of my pants. Your information helps me to assimilate how all the variables work. Loved your statement,”the leaves go the work”. So true. Thanks

Hello, you do the hot or cold dyebath when you use the Myrobalan?

Tks

Manuela

It can be both. If I just made it, then it may still be hot but cold will work as well since the dye left in the piece will get the heat from processing.

Wow! I’ve a doubt. Im from India and literally myrobalan is in my home always!

I’ve some rock pigments & plant pigments. If I make them paints, using some natural gums, can I use them to paint on a cotton cloth soaked & dryed in just myrobalan tea? Will it be wash-fast ? Or, any other processes needed ?

Hmmm, that is quite interesting! I have not made fabric paint. I know that printing on cotton means it should be prepared by mordanting first. When you are not sure, do small test prints with what you have and also wash test and sun test.

More!!!

Thankyou!

Hi Barb,

Thank you for your generosity ❤️ whenever I need to read about ecoprint your blog is the first place to search 😄

Recently I struggle to get very darck background and colourful leaves’s print at the same time.

I used myrobalan a gall. I soaked my silk in iron then put leaves on it and cover it with the tannin blanket. The background will come out nice but very pale. Once I soaked my silk in tannin tea and cover the medium with iron blanket, but the result was disappointing. I didn’t have any print in my silk, instead I had a very dark background on my blanket and lovely shades! It is very confusing! I couldn’t figure out how to get very dark background on my main medium 😅

That sounds very strange! Maybe you should do a bit of experimenting. You can even just play with the myrobalan and iron.Perhaps your tannin is not strong enough, weak iron, or fabric that is not true silk. Myrobalan and iron react so quick, I even did some tie-dyeing with it. Iron will give a dark leaf print though if fabric is dipped in iron. The weak prints can still also be reused for more effects ! Don’t despair, it’s all part of the learning process…

Thanks for this Barb! I’ve been eco printing for the past year and looking into new techniques. This came in handy!

That’s great! I like the fact that there is so many ways to switch it up and try different combos, blankets, mordants and dyes.