DIY Life Cast Concrete Hands

Let me tell you; Life Casting is a magical thing! I have played around with it in the past but this time the purpose was to make the ‘master’ for a concrete mold; DIY Life Cast Concrete hands. There are many steps in this tutorial but in the end you will have the most unique and personalized concrete sculpture!

I had to wait til I could find a suitable subject; someone who would let me use their hands. I can’t do both parts myself. So when my daughter came for dinner, the payback was a bit of Life casting of her hands!

The Supplies for the Master Casting:

- dental grade alginate (I used about 1/2 pound )

- a vessel of some sort that will fit the desired shape

- plaster of paris

- some carving tools (simple knives, files, sandpaper)

Life Casting the hands:

Practice the shape that you are hoping for, trying not have too many odd voids. Alginate is the material that is used in the dental industry to cast the mouth quickly and safely for making retainers etc. It is amazing for Life Casting since it picks up the finest details but is also ‘rubbery’ enough to allow removal of some pretty complex forms like hands. It is however considered a one-time casting media.

It is always a good idea to do a small test to avoid any expensive mistakes later on. If you are really curious how Alginate works; make a tiny test sculpt of a finger. The working time will depend on your brand and kind of alginate, but in general it is REALLY fast since it is made for those kids in the dental office. Some even have a colour change to let you know it’s ready to unmold. I’d suggest finding the closest dental supply place to order from or here.

I envisioned that the bottom didn’t matter too much since it was going to be a flat botttom in the end. I needed a bowl to contain the mix around the hands since it is pretty fluid when poured. Once set you can just gently wriggle the fingers and pul the hands out. It has a fair bit of ‘play’ since it is flexible. The bowl is vertical since the shape would collapse once the hands did not hold up the middle, this would keep it’s shape.

Pouring the Plaster:

The alginate is best used right away (not the next day) as it would dry out. Mix some simple plaster of paris and pour into the mold making sure to ‘slosh’ it around to get into all the finger cavities. The tin foil was my attempt to fill some extra since I had run out of plaster. (that’s what happens when you get over-excited)

The plaster will warm up and set. Once it is hard you can peel and break up the alginate.

This is so much fun to see the details. Don’t worry about small imperfections, as you do have a chance to fix it. You will be amazed at how this Life Casting picks up each wrinkle in the skin! Again, it can easily become an addiction. I have had craft fun with kids casting shallow imprints of their feet and hands in plaster and putting in a shadow box frame.

I was squealing with joy as I was breaking it out…

A few bubbles, but that is ok! All fingers were there!

Success! The plaster may still be damp and need to dry out. My impatience had me cleaning up some of the small bits right away, but be careful not to break off any fingers!

Plaster is soft enough to carve into to adjust any small details or fingernails. I also filled some of the bubbles with some mixed plaster. Yes, I know, I’m a perfectionist…

This is the stage where I decided how they will sit, flat bottom. So I cut and shaved off the bottom and finished off the wrist ends. The bottom will be the pour opening for the new mold.

This is the final plaster cast; pretty amazing isn’t it?! Now, you could stop here but then you would only have one…

Plaster is porous and I was afraid my favourite casting material would stick so I brushed on the wax/vaseline mix.

Supplies for making the Mold:

- ‘Your amazing Plaster-Cast hands’

- 100% silicone Caulking & caulking gun

- vessel/bowl to mix in

- cornstarch

- sharp xacto/matt knife

- release agent (vaseline, or wax/vaseline mix)

Use a sharp object to pierce inside the tube or the attached ‘doohicky’ on the caulking gun. Don’t forget this… as you will burst the tube if you try without poking it first! (Don’t ask me how I know)

This is a fairly large mold so it will need prob the whole tube, but still quite inexpensive.

Glove up and cover with cornstarch. Try to keep cornstarch between your fingers and the caulking; less sticking. Keep incorporating the cornstarch until you notice it not sticking and becoming a stiffer moldable material.

Mold it into a ball and then flatten enough to somewhat stretch over and around the shape. Push into the form and get even coverage. You will be able to feel the plaster poking through if it is too thin. This shape is unique as it has a hollow in the middle of the hands, keep it an even layer as well inside. The thicker the walls; the less flexibility the mold has to remove. Let it set for about 30 minutes or til not ‘squishable’ any more.

I figure the best way to open was a center cut up the middle and around the ‘bowl’ shape. Cut carefully until it touches the plaster. This silicone/cornstarch mix cuts nicely!

If you can get it out now, you will be able to get out the concrete later for these Life Cast Concrete Hands.

It took a fair bit of wriggling to get the center out. If need be, carve back the mold to allow more bendability. TADA! Mold is done!

Casting the Concrete:

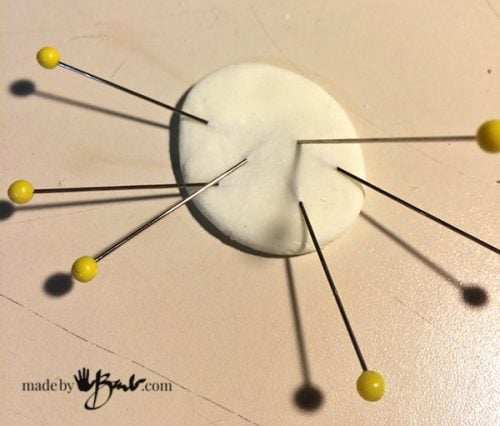

I INVENTED a new way of readying the mold for casting. Yes, elastics work great if holding the outside together but I needed something better for the other areas. Professional molds have tabs and clamps which this doesn’t.

I tested long quilting pins and they do not leave any holes; ie they ‘heal’ themselves – great! Perfect for temporary attachment.

Supplies for Casting The Concrete:

- Rapidset Cementall mix (and dust mask)

- Concrete Reinforcing fibers (optional )

- A plastic bowl for mixing

- water

- mixing spoon/device

- elastic bands

- long quilting pins

“X” Pin the sides that hold the inside of the ‘bowl’. Only pin through the mold material, not through the voids.

All lined up and pinned

Turn over and secure the outside with elastics.

Now that is ready; mix the Rapidset Cementall. This sets really fast and is quite strong.

This mix uses less water and it incorporates quickly.

For extra assurance, add fibers. If you don’t have any, just be more gentle when unmolding. I have not had any fingers break either with or without. For the best flow have this mix on the runnier consistency.

Fill the mold (opening on the bottom) and tap/vibrate well. You have a lot of fingers and details in these DIY Life Cast Concrete Hands!

Level the mold and let for 1 hour or more (love this rapidset!)

All set and still warm.

Take out pins and elastics. Open the front of the mold and peel back around to expose the sides.

The centre is a bit trickier to pull out, keep working it carefully around til it lets go.

There are some undercuts here that make bending the mold required. It will depend on your exact form. (The nice thing; you have an original plaster cast that can be remolded if this does not work)

There may be a few seam lines from slight leakage.

Use a file or some strong emery cloth to smooth the seams or bits. Do this before it is has cured 24 hours.

I love how rustic these DIY Life Cast Concrete Hands turned out. You can see details of skin but it doesn’t look like plastic! The bird just ended up sitting in there by accident. If you are new to this mold making perhaps you’d like to start with just casting a bird and then practice pouring your mold.

This could be a planter or a bird feeder or change holder or key holder… But will be a ‘concrete’ reminder of that special person!

Hi great info! I was wondering if you could use the dental grade alganate alone as a cocerte mold? Like a one time use mold, would it hold up pouring rapid set directly into the alginate? Thanks for the information

I have not tried it but I think it would work since the plaster did! I would use a fast set though so the alginate does not dry during the cure.

Awesome thanks for the Information. I’m going to try it!

I am wondering if pouring concrete directly into the alginate worked. Would you please let me know? Thank you

Yes, it would , just be sure to get all the bubbles out. It would obviously only be a one-use mold though.

Okay I’m sorry but the silicone mold absolutely did not work for me. I’ve tried twice and it doesn’t hold up…..just flops around and had so much leakage when I poured the concrete it ruined the whole thing. very frustrating. Need to finish up a project and can’t figure out how to make a dang mold of the plaster hand.

Wow, I can’t understand what went wrong. Can you tell me the exact caulking you used? (should be 100% silicone, NOT latex) And you used cornstarch? I get a flexible but also pretty stable mold. I also notice they last really well. Very odd…

I love doing that kind of work

definitely gonna try

Alginate is so much fun, but it helps to have some extra hands when trying to use your own for casting! Good luck!