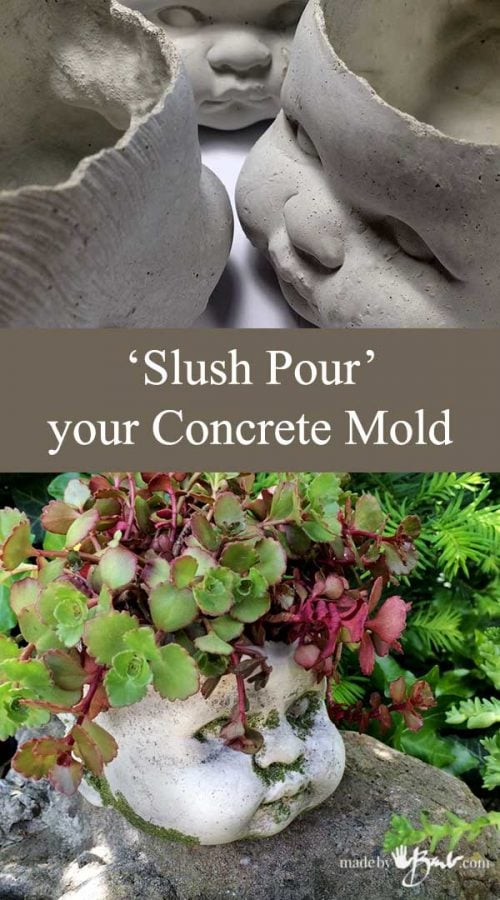

Slush Pour your Concrete Mold

Move over ‘Chia Pets’! Everyone is allowed to be silly sometimes, so it’s my turn. Yes, a ‘head planter’ is a bit odd but it’s purpose was to test a new casting system. Make your concrete pouring simpler and see how to slush pour your concrete mold. I love this method! Besides, I could not resist that baby pout!

To start this mold making I used this cute little fellow…

And I popped his head off. (Don’t worry, he is back together now)

My inspiration is this favourite planter of mine. She has aged well and her veil keeps growing gloriously…

Find yourself some type of head or perhaps even a mask.

Before casting I needed to fill the hole on the bottom of the neck. A quick patch of — ya, duct tape!

Tools and materials needed to make the form:

- 100% silicone caulking

- cornstarch

- head form

- gloves, bowl (mixing)

- rubber bands/pins

Materials to Cast and finish Concrete:

- RapidSet Cementall & Water (mixing container, utensil, Dust Mask, gloves)

- Concrete reinforcing Fibers (optional)

- Landscape Grass Flocking (moss)

- Liquitex Acrylic Matte Medium & black acrylic paint

- Brushes

Making the Mold:

The method to make this mold is the same as my first mold making tutorial. Lightly apply some vaseline on the master shape (the head). Mix the cornstarch and silicone carefully in the bowl without getting it all stuck to your fingers. Add cornstarch (just as you would add flour when working with dough) until it becomes workable without sticking.

It should be pliable to spread it around the ‘head’ and keep pushing it till it covers up to the rim of the head and fills the bottom. Spread it until it is an even thickness of at least 1/8″ thick.

It will set in about 30 minutes. Once it is completely ‘rubbery’, you can cut up the back, or at each ear side. Remove the ‘head’, adjusting by cutting as needed. I am alway amazed at the strength of this recipe! Mold is done!

Slush Pour your Concrete Mold:

To ready the mold, use elastic bands to keep the seams closed. Since it is a round shape this works well. To ‘line-up’ any seams you can also use my trick: securing with pins. This works well, as they make sure the edges stay together and later pull out without leaving a hole.

As with many of my projects this casting method works best with a strong, rapid setting concrete. This concrete is quite ‘plastic’ and will mix better if water is added first, and then slowly add premix until it has some flow. It has a working time of about 10 minutes. The flow should be ‘slow’ and somewhat thick.

Pour it into the form and start to turn it to coat all the inside. It may take a bit of trial and error until you have the right consistency. Turn slowly and watch for the flow to eventually stop. I discovered this slush-pour method when making the ‘balloon-cast’ monster eggs.

It may not be pretty, but it is easier than having a center form. Let it sit for an hour and then repeat and pour another layer. Depending on the thickness, you may need a third layer. This concrete is VERY strong and can hold well at only 1/8″ thick.

The top edge may be a bit uneven as well, but you can sand it as desired. As a planter it looks quite nice as a ‘broken’ edge style. Don’t worry about any texture that the mold has picked up, it IS concrete afterall.

To make it look aged, use some ‘washes’ as in my antiquing tutorial.

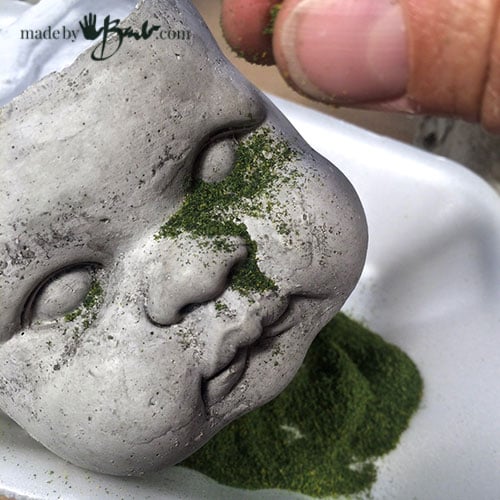

Instant Moss:

Do you want the ‘mossy’ look instantly? I came across some of my flocking material from my days as a ‘model builder’. It is also used in model train landscaping and can be found at hobby shops.

To adhere the flocking; use a bit of matte medium. Brush it in places that would naturally grow moss; areas that would tend to be in shadow.

Sprinkle the flocking into the wet medium. It’s the same method you would use for glitter. It’s your preference how much or little. To make it less likely to continue to lose bits, add another layer of matte medium. (If you can’t find flocking maybe you could put some moss in a sacrificed blender/coffee grinder)

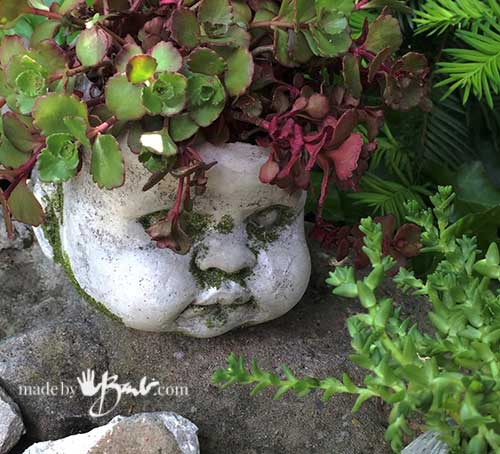

I have tested some sealer methods (soon to be posted) before I planted up these fellows. Succulents are my favourite as they never seem to complain and they propagate like crazy!

Quite the hairdos! But this method is not limited to heads. (more projects in the works) It is somewhat reliant on a strong mix or perhaps a thick wall of multiple pours.

Happy casting and planting!

Can’t get enough concrete projects?! Check out my concrete obsession

20 years in creating branding and trademarked content for clients here. Simply using a doll head as a mold to make your own planters is in no way illegal. Once you purchase a product you are free to do anything you wish with it, except, sell the derivative. Only the original artist/manufacturer has the legal right to sell their work in mass. A one off sale of the original item as used can be done numerous times to different people, but creating multiple copies of someone else’s work and then SELLING them is where you get into illegal territory. You could easily get around this by sculpting your own doll head out of air dry clay and then using that to create your mold.

Interesting information. I see many who buy ‘old’ items and change them into something else. Yes as a small craft for self use is fine. Many ask for the mold of my Large face mask and do not understand why I would want a large amount of money since they could essentially make 1000’s. Always something to learn…

Hello Barbara,

Looking to find where are these fantastic HANDS for planting a bougainvillea or a tree?

In advance, thank you kindly,

Edith

I’m confused! My HANDS are in Canada!

Hi Barb

Cement All rapid set is quite expensive so i need to use sparingly. In flat slab castings of 1 and half inch thick, I want to pour the first Cement All mix just enough to cover the base and detail of the mold and fill up the remainder or backing of the mold with an ordinary Portland mix. Like a slush cast. How long after pouring the Cement All can I pour the rest of Portland mix in? Does the Cement All need to set completely first or can I pour Portland mix directly after? Do I need to add any additive or will the two products naturally bond on top of each other if still in slurry state?

Appreciate this great blog and your time and assistance. PS. I am in SA what does a Bag of Cement All Rapid Set cost in $ USD where you are at?

Regards

James Bravery

Hi there! I am in canada and a bag costs about $30 for 55 lbs. I understand your idea and I think it can work. I also think that as soon as the Rapidset is stiff (but not cured) you could add the portland cement. Whenever I add to older concrete I make sure it has been wetted so it does not suck out the water from the new add. But Portland cement is not that strong by itself. Maybe it’s best to add some fine sand to it, however then it may not flow as well. 1.5″ think is quite thick! I use a sandtopping mix to make stepping stones that are less than that thick and they hold up quite well. Hope that helps!

I wanted you to know how long your tutorial has been inspiring people. I see comments from 2017 and it’s now 2022 and I just found your site. Your tutorial is beautiful! I collect head planters and place them around my flower beds, my covered porch, and inside my house! My adult daughter and I have repainted and costumed Barbies, then got the idea of turning baby dolls into old crones or zombie dolls for Halloween. Such fun to use dolls! Thank you for the tutorial. I will definitely be trying this soon.

It’s about time that you found me… I have much for Halloween as well, especially the famous Spook!

Hi! Would this mix hold up if submerged in water? If not, which one would? Thank you

Well, if it was cured I don’t see a problem as I did redo the inside of a birdbath with it and it has been a couple years already. My concern is though; will their be any fish life etc? Then you may need to address what comes out of the concrete…

I didn’t see where you released the mold from the head..

did it just pop off? how long to leave the head in the mold??

There was a slice down the back which was boing held closed with an elastic during the pouring. That allows the head t be pulled out easily when cured.This mix cures fast so one hour is usually enough. Regular concrete will not be strong enough for this. Hope that helps