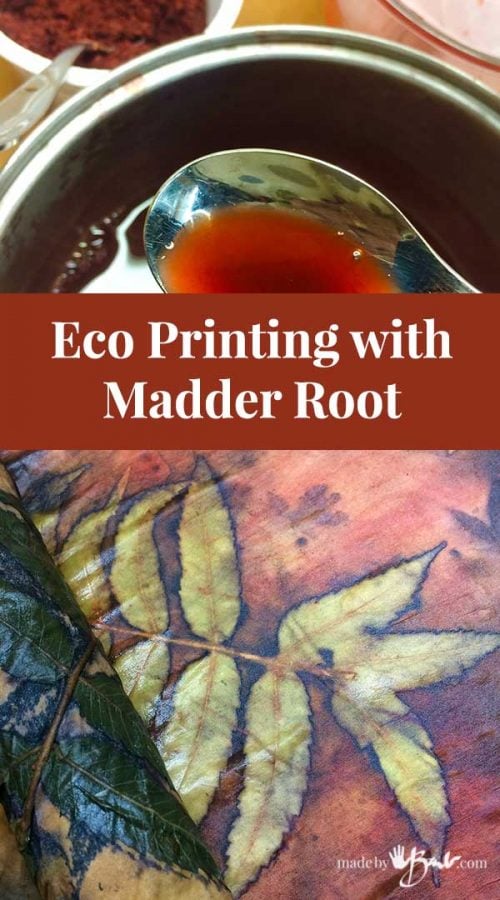

Eco-Printing with Madder Root

When I embarked into the vast world of printing and dyeing with natural elements I never knew that ‘wood’ could provide so much colour. Imagine a root that can ‘gift’ you such amazing rich reds… Eco-printing with Madder Root is such a delight.

Madder Root comes from the tree Rubia tinctorum. The roots provide a variety of reds, from orangey to bright red. Factors such as the soil, the water during growing and temperatures during dyeing create different red outcomes. It is not a very expensive dye but does need a fairly strong brew.

The Little bits:

In this process of eco printing I am using habotai silk. The amount of madder root to fiber (fabric) should be about 100% to WOF (weight of fiber) if a strong red is desired. It is still your option to increase or decrease the potency. My madder root came in a slightly coarser consistency than what I used prior but it will all work. The coarser the ‘grind’ the more you will need to do to get the pigment out of the roots. To keep the reds stronger and less dull do not boil the solution of madder root and water, it should remain lower than 80 degrees celsius. I like to give mine at least an hour and sometimes let it sit overnight as well.

If it is a powder you may immerse your fibre with it but it may still be messy to rinse off. I like to strain the ‘roots’ from the ‘madder tea’ with the use of some sheer polyester organza fabric (like old curtains).

Once well drained, squeeze as much as possible from the steeped roots. I like to collect the ‘matter’, let dry and save for a possible weaker solution next time… and it’s what us crazy dyers do, never waste anything!

The Madder Dye:

Such wonderful earthy reds. There is some belief of using calcium carbonate with the dyeing of the madder root but I did not use it.

I like to keep things simple and find that the habotai silks (protein fiber) dye quite well without a pre-mordant. To allow best colour absorption I like to steep it below 80 degrees for as long as I can, again possibly over night. Much depends on my impatience… It should move freely in the solution to get the most even dye application.

In this process i add the botanicals after I dye but that’s my choice, not a rule. There really are no rules in Eco-printing as it was probably discovered by breaking rules. I generally just wring out the silk and use straight away.

My Bundles of Joy:

To get the most distinct prints the contact with the fabric should be as tight as possible. In this process used an iron blanket to give extra definition as the tannins in my leaves combine with the iron to make permanent marks.

I have used steaming in this case but do also use the microwave processing with success. The very interesting thing is that the tannins in the leaves created a chemical reaction that made the dye change where they were placed; as if it displaced the dye.

Since the sill is such a fine weave it picks up such amazing detail. The iron does also combine with the madder and darken.

Always something different:

The nature of this art form is somewhat unpredictable, but that is what makes it so interesting and keeps challenging us. This scarf was printed a couple times hence some dark prints and some resist prints.

Maple and sumac have much tannin so they create great resists.

The reds were quite ‘saddened’ in this case where my iron solution on the ‘blanket’ was a bit too strong. There are still red undertones and a lovely gold resist that are captured in such lovely shapes.

Alright… can you tell I am a bit obsessed?! I absolutely never tire of opening a bundle! ‘Kinda like checking your lottery numbers but in this case I almost always ‘win’ something beautiful.

Join me in the ‘game’.

Just stunning Barb..the colours are truly beautiful. Mother natures pallet is glorious 😊

Where are you getting your Madder root from? Wouldn’t mind turning some of that root perhaps if it is large enough.

Fascinating! What a wonderful outcome too! Have you tried any of this eco printing on any of your cement work? It would look splendid on some cement vases! I wonder if that is possible.

I put some of my little cement planters in a bucket of water and then some old leaves fell in it and stain the little pots with some rusty looking colored areas. Might be something to try to do on purpose.

Just wondering how to make an iron blanket thanks Barb. Love your work so very much. Cheers Tracy.

Thanks, I love this art form! It is a cloth that is soaked in a ferrous solution (rusty iron water) How strong will determine the amount of greys and blacks. You may want to check out other posts as well. Happy Printing

Hi, Barb

Thank you for sharing your art, you are such an inspiration.

Do you have tutorial eco print on leather?

So far I don’t, but I have tried a few test runs… stay tuned!

In one of the pictures your leaves look like they are being dipped or soaked before added to the fabric? Were they dried? Or are you dipping them in a mordant?

Thanks! Your blog is SO helpful and inspiring!

In this case the blanket brought the iron so the leaves were not dipped. Maybe they were rehydrated as I keep a stock pile of dried ones

Hi barb, I love your work and I am trying to learn it. One of the problems I’m facing is sourcing of leaves that are rich in pigmentation like eucalyptus, maple and walnut.

Do you provide that?

Well, one of the reasons I love eco printing is that I can just go outside and get supplies. Maple, sumac, rose, blackberry, acaccia, Weigela, and more just grow here. The only one I may buy is eucalyptus at a florist but even then, you are not guaranteed to get the specie that gives reds. After experimenting you will find your favourites and know where those trees are.

Hi Barb, your passion for eco-printing has rubbed off onto me. I think I have watched every video you have posted. I haven’t started printing on fabric yet but have purchased some just waiting for some courage. HaHa My question for you is; can the natural dyes that you use be used to eco-print on watercolor paper? Thank you for sharing your expertise!! Kris

Oh yes! Printing on paper is as much fun & I have great results with just cheap card stock. See these posts The leaves are just coming out here… ‘can’t wait!

How long do you let your bundle sit before you open it? And how long do you steam for?

Generally I like to let it sit for a bit but a lot of eco printers say that does not matter. I have switched to using the microwave for almost all my processing now (let sit insulated over night). If you steam; I’d say for an hour. If its a dense bundle (many layers) then more time… It’s a science that needs experimentation.