How to Make Cyanotype Prints on Fabric

As soon as the sun gets strong and the plants are in their glory I think about using the sun to print! It’s a prefect reason to get outdoors and get creative ideas flowing. I’m so pleased to introduce how to make Cyanotype prints on Fabric with you!

What is Cyanotype?

Cyanotype is a process that utilizes UV (sunlight) to create prints. It is a photographic method that quite inexpensively creates a cyan blue print. Variations in the technique can allow many creative solutions. It was invented in 1842 by Sir John Herschel. It involves a couple chemicals; potassium ferricyanide & ammonium ferric citrate. If you would like to learn the chemical theory you can read here.

I am excited to use this process as I am passionate about using dyeing in my creative use of fabric. I do also have very vivid memories of the days in the darkroom developing my own black & white photographs & prints.

What do you need to Cyanotype on Fabric?

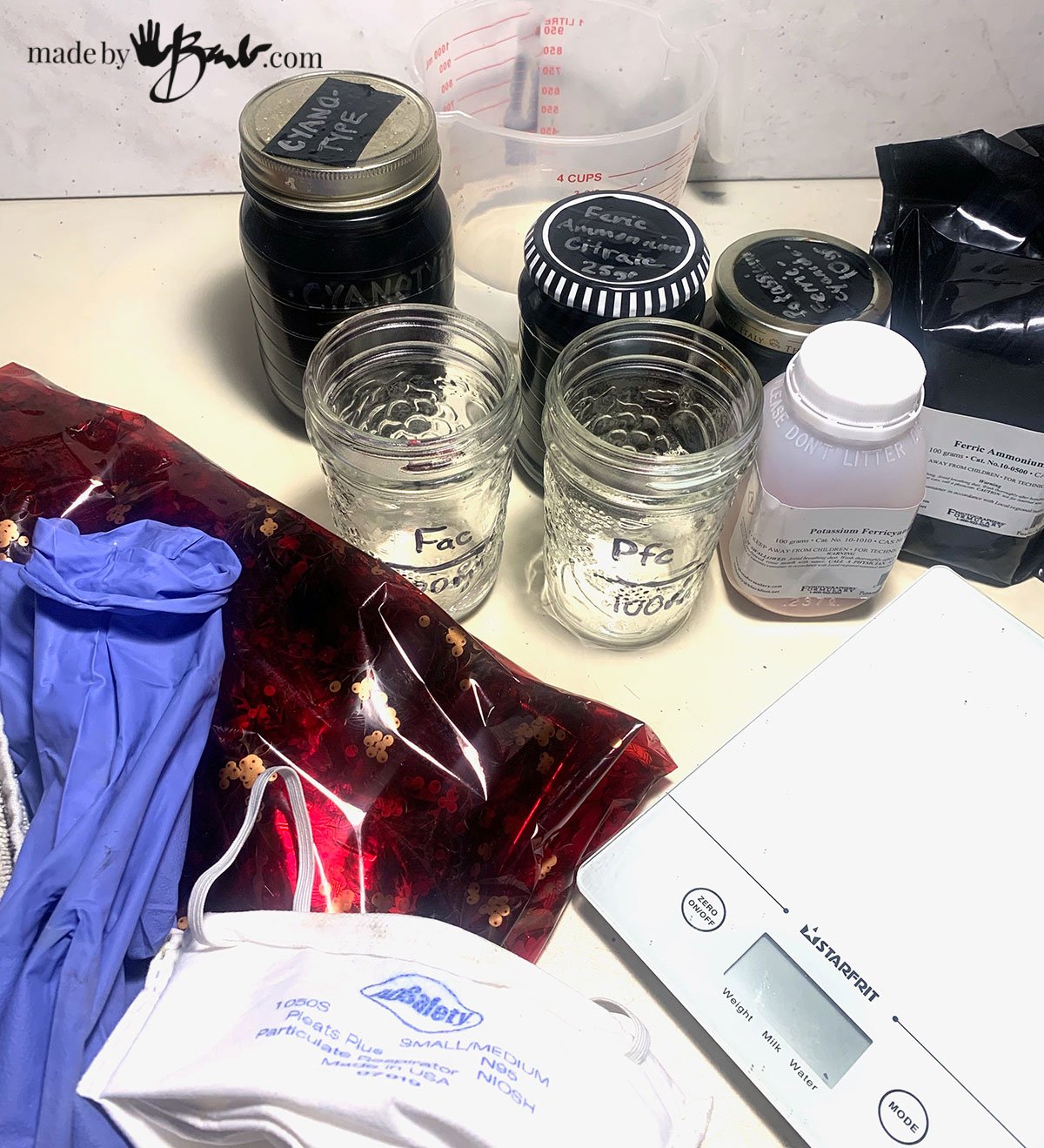

There are two chemical compounds required to create the cyanotype solution, Potassium Ferricyanide, and Ferric Ammonium Citrate. I bought a bit larger quantity from a photo-supply store but you can get convenient kits as well. There are options to buy pre-treated cyanotype fabrics and papers as well.

The basic recipe of cyanotype chemicals is 10g of Potassium Ferricyanide mixed with water to make up to 100ml. Measure 25g of Ferric Ammonium Citrate and add water to bring it up to 100 ml as well. Mix these two solutions together and keep in a dark container. The solutions should be well dissolved and it is also recommended to sit for a bit for assurance.

The fabric should a natural fibre like cotton, linen, hemp, silk, rayon etc. Make sure it is clean and scoured. I am using up some of my stash of denim, bleached and light.

Stay safe and use gloves and a good mask while measuring the powders. Prepare your work surfaces in case of spillage. You will. need a scale to measure the chemicals

Prepare a vessel to hold the chemicals once mixed. Since the mixed solution is light sensitive it needs to be stored in a dark bottle. You can wrap a jar with black electrical tape if need be.

How to make the Cyanotype Solution:

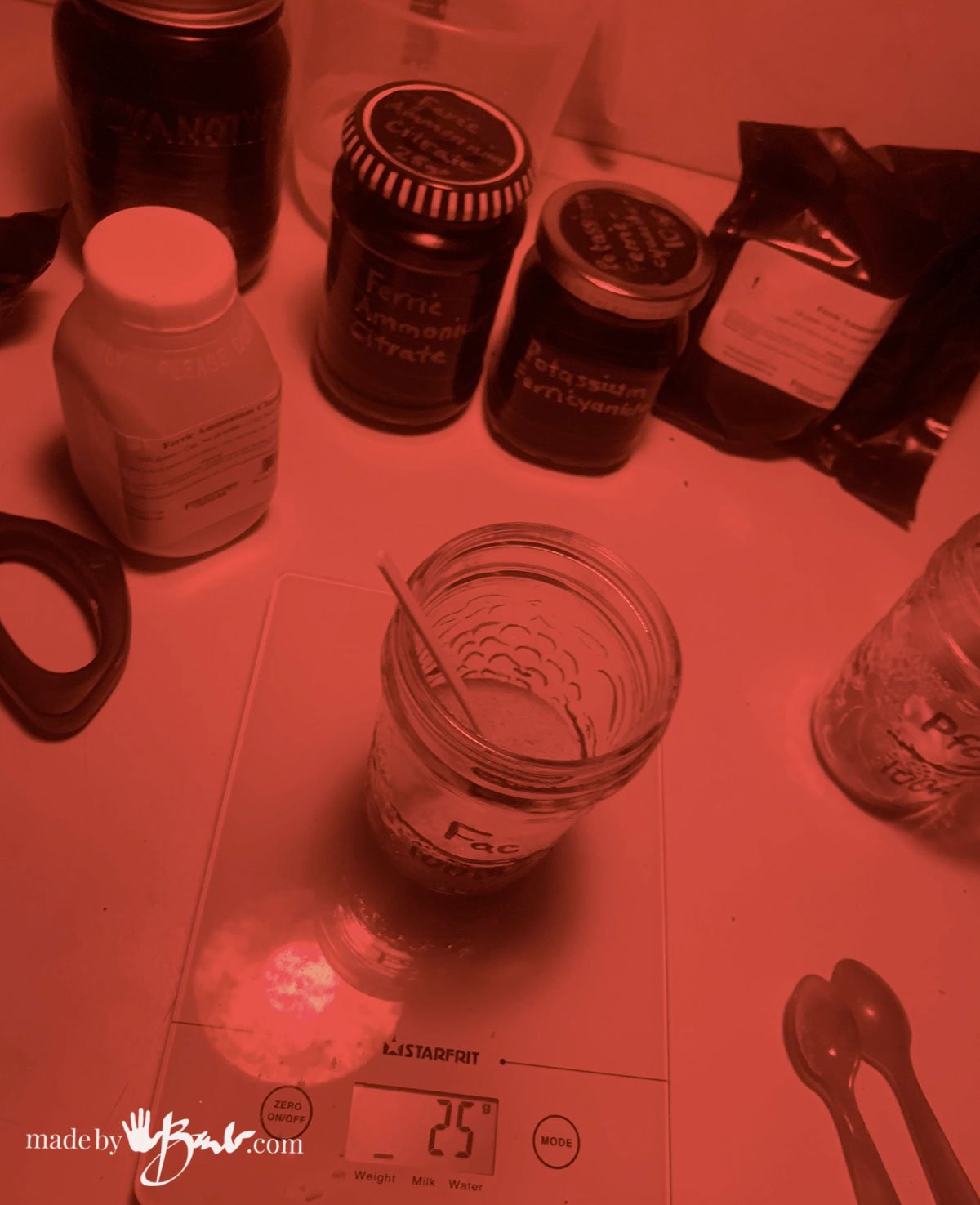

Since the solution is light sensitive I covered my light with some red cellophane. I recall that was what we similarly had in the darkroom for photography. The LED and Incandescant bulbs we have do emit a bit of UV rays to I was extra cautious. I also covered the window.

Measure out 10 Grams of Potassium Ferricyanide into a jar and add enough water to bring to 100ml volume. Mix carefully.

Measure out 25 Grams of Ferric Ammonium Citrate into a jar and add enough water to bring to 100ml volume. Mix carefully.

Combine the two solutions and allow time to fully dissolve. Use once dissolved or keep in dark til ready for use.

Preparing Your Fabric:

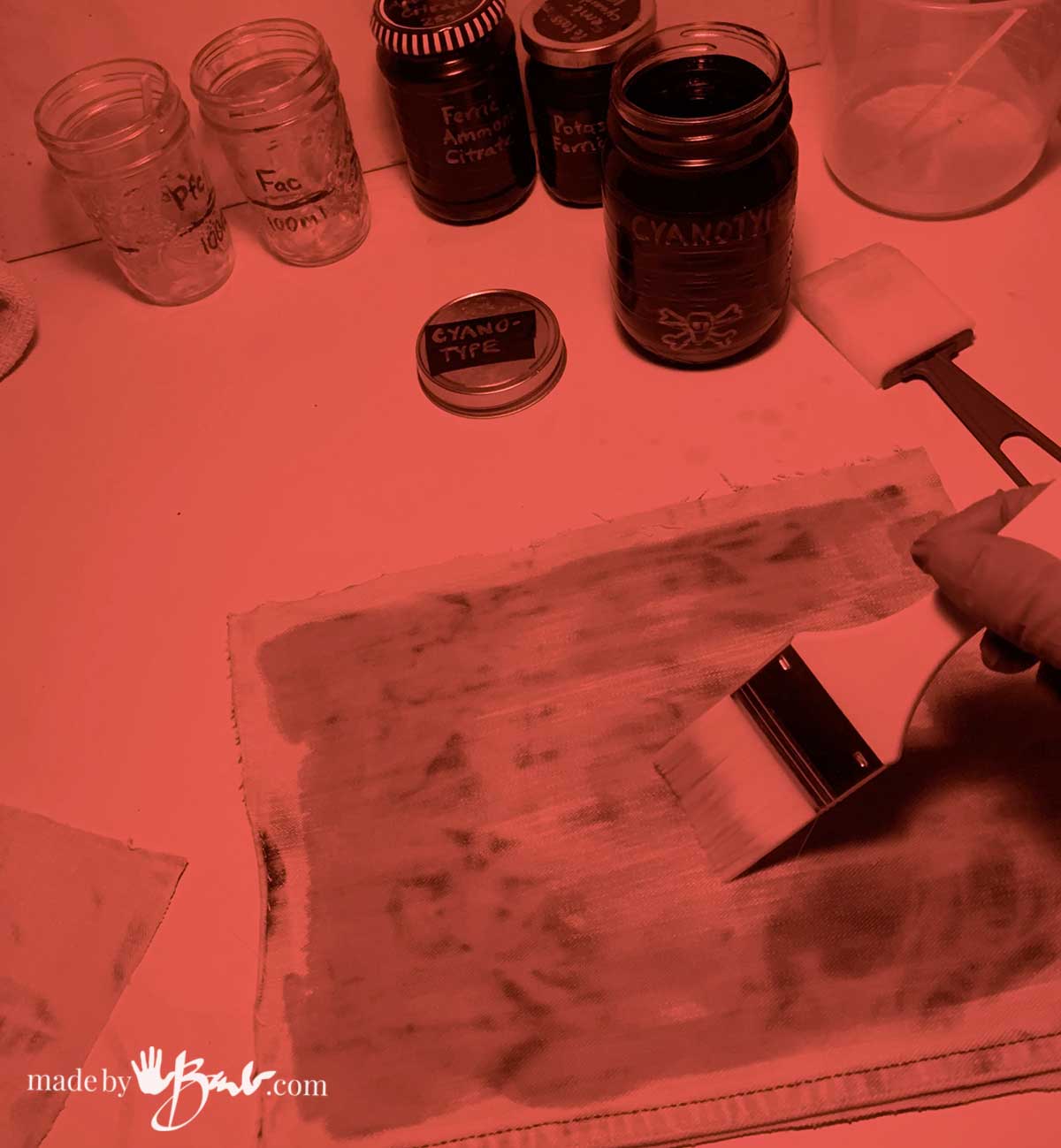

Once your solution is ready it is only a matter of applying to the fabric (paper is the same process). Choose a brush or foam brush that does not drip too much and is soft enough to spread the thin solution. This part of the process also happens in low light or dark.

You can expose the wet fabric with designs to the sun right away or let it dry. I opted for letting it dry in a dark closet so that there was less chance of contamination.

What to Use for Cyanotype Designs:

Well, this is really only some suggestions as there are so many possibilities of what to use for a cyanotype print. Some of the easiest things are botanical plants, leaves and flowers. The uniqueness of the print comes from the choice of material. Light can pass through a variety of objects to make creative prints. Things like fabric, lace, thread, can also create a detailed print due to their nature. I am planning on digging out some old negative films as well (stay tuned). This opens up a lot of possibilities for printmakers and artists who do not want to draw.

Any roadside ditch can have amazing specimens if you are looking for botanical things. Look at the lovely lines from some old weeds! You have endless options of how to lay out your designs.

Prepare Your Cyanotype design:

Since the fabric is now UV light-sensitive you should work under low light conditions to place objects & arrange your designs. The key to getting clear crisp prints is the amount of contact the objects have with the fabric. Ideally they are flat and pressed down to allow no light to sneak underneath. I love the way small blossoms (even maple tree flowers) give detailed shapes. Experiment with adding whatever elements tell your story. This is perfect for media artists!

To keep everything in place it works well to cover with something like a sheet of glass or plexi-glass. Anything that will allow the light to pass can work. Binder clips will make sure it stays in place.

How to Expose your Cyanotype:

My preference to expose these is to use the direct sunlight on a bright sunny day. To make it easier to transport my boards I place them in a double garbage bag until ready to put on the table outdoors. You will notice the yellow-green colour in almost no time it will be darker blue.

The exposing happens quickly and I found that 5 minutes on a cloudless day was enough here in Canada in May. You could make yourself a test piece with a cardboard strip that gets moved every few minutes to assess exposure time differences. Myself, I work more like an artist than scientist…

(NEW) I have now also added a way to print indoors with a LED UV Light. This makes it so convenient and allows me to print whenever I like. See how to Make an Easy Indoor Exposure Light for Cyanotype Printing

These are already exposed enough. If you over expose the light may start to pass through the specimens and the prints will become less. ‘But there is no right or wrong as that may create extra interest.

When ready take the board indoors and quickly move to rinsing since the parts of the print under the objects could still be exposed.

It is magic when you remove the objects and see the details! Perhaps I can find some variegated leaves for more details. Another good thing is that these objects can be used again. If you dry them they can be used over and over….

Washing the Prints:

The sun-exposed fabric now needs to be rinsed of all the chemical that did not expose. That is why you will see a yellow rinse water. Keep rinsing in the sink until only clear water comes out.

Even more details show up after you rinse out the extra chemical. Is it not amazing what the power of the sun is?!

The colour of the cyan is beautiful. In the printmaking world this method of using objects is called a photogram.

Darkening the Print;

The print will darken as it oxidizes more or you can add a capful of hydrogen [peroxide into the rinse water to expedite it. See above for colour difference.

As you know I love blue & white; shibori and also ice dyeing. This ‘ups’ my game and there’s more challenges I want to put this through. I immerse myself in all aspects when I learn something new. ‘And I love that I can use up some of those old jeans…

Caring for you Cyanotypes:

These are washable however phosphates and alkaline environments are not recommended. Most detergents are now phosphate free but testing is recommended. Washing should be done in cold water and use a pressing cloth with a dry iron if needed. Hang to dry and keep out of long exposure to direct sunlight.

If you want something different than a blue print you can ‘Tone’ the finished print for a variety of outcomes. Check this new post: How to: Tone Cyanotypes with natural Tannins

Thanks for the inspiration! I have yards and yards of linen to play with.

Real linen is a treasure these days! I love to use it for tea towels as it is more absorbent than cotton. Also wonderful to Eco Print on. (linen pouches)

Hi Barb, thank you for this great explanation.

is there anything you can do to the finished print to stop it fading, apart from keeping it away from the light? It seems such a shame to hide away something so beautiful. Many thanks. Lesley

I have yet to experiment with a UV protectant varnish. I suppose it would also change the feel of the fabric. Using a solution of peroxide is supposed to rejuvenate the print after some fading as it does when in the processing stage. I should do a troubleshooting post…

Hi Barb. I have not thought this through, fully, but could one combine this technique with ice dyeing….either over or under?? I am an ice dyer, and wanting to try something new with that technique. Thanks. MJ

Well, that would be a tough one. The fibre reactive dye needs the help of the soda ash which would react with the cyanotype chemistry. You could ice dye and finish with a good wash so that it is now just a clean dyed fabric, then go from there. I do plan to experiment with some toning of cyanotypes soon, which may give you the variety you seek. ‘But feel free to try things… There are ways to combine tannins with cyanotype prints; which interests me since I already have some tannins. (Sumac & Myrobalan)

Hi! I was wondering if you had recommendations for printing on 2 sides of fabric. Can you expose one side and then place cardboard inside the fabric and flip and expose the other side without washing in between each side?

It will depend on the transparency factor of the fabric but yes you should be able to print both sides. This post also helps figure that out with some cool tricks. ‘When in doubt; do a tiny test…

Amazing instructions. I’ve just begun upcycling denim and saw a picture of this technique. I hope to try it. Nice to know you’re a Canadian, too! I live in Oliver, BC

Thank you for your inspiration.

Avis Cooper

Thanks! I love this process too. ‘And who doesn’t have a lot of denim to upcycle?! Jackets and clothes look so cool with Cyanotype. Happy Printing!

Our sewing group made cyanotype prints last summer with pretreated fabric. I had a few pieces extra that I intended to do within a few weeks of our original session, but then life happened at it is now almost a year later. Even though I had those extra pieces stored between opaque cardstock and in a brown enveloped, when I pulled them out yesterday they were dark blue. Is there a way to “restore” the cyano-property without having to buy chemicals?

An old, unexposed cyanotype solution turning blue indicates that the ferric ammonium citrate (FAC) has degraded, likely due to light and moisture exposure. Cyanotype chemicals, particularly FAC, are sensitive to these elements and have a limited shelf life, even when stored properly. The blue color signifies that the iron(III) in the FAC has been reduced to iron(II), which then reacts with ferricyanide to form the blue pigment Prussian blue, even without exposure to UV light. If I were you I would still try a print and see if there is some interesting result even though not ideal. I do love to experiment! At this point you don’t have much to lose!

Can this be done on a stretched canvas??

I have not printed on a gessoed canvas as it is not that absorbent of a water based pigment. If it was a raw canvas, almost like denim it would work. The issue that could happen is the edges near the wood frame could be affecting the absorption of the solution. Personally I would test a small canvas or print a large canvas fabric piece and the stretch it on a frame.